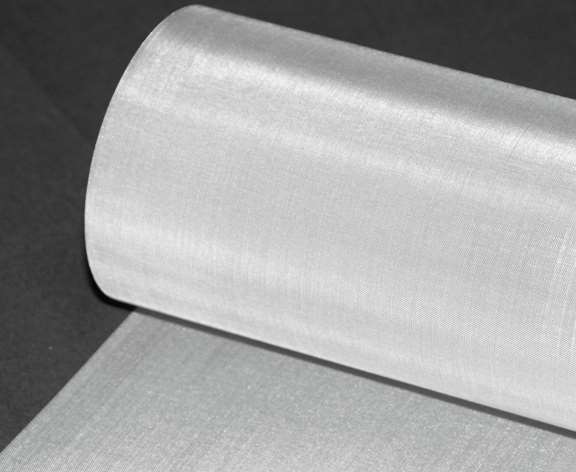

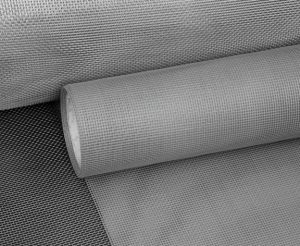

Woven wire mesh is made from wires in metal or synthetic materials. The wires are woven into a mesh in a long piece, typically about 30 meters long and 1 meter wide. The wires can be as thin as 0.016 mm (16µ) in diameter.

There are several different ways to weave the mesh. We typically work with the methods "Plain Weave“, “Dutch Weave" or "Twilled Weave“.

The optimal type of weave type, mesh size, and wire thickness for your needs depend on what the mesh will be used for and what it will be exposed to. Our wire mesh has different properties concerning, for example:

- Filtration capabilities – i.e. how fine are the particles to be filtered

- Filtration method

- Mesh strength in relation to flow, pressure, and vacuum

- Extrusion capabilities

- Hygiene and cleaning

WestCoast supplies mesh in rolls, custom-cut mesh, filter cylinder, strainer, basket filter, mesh on a frame and much more.

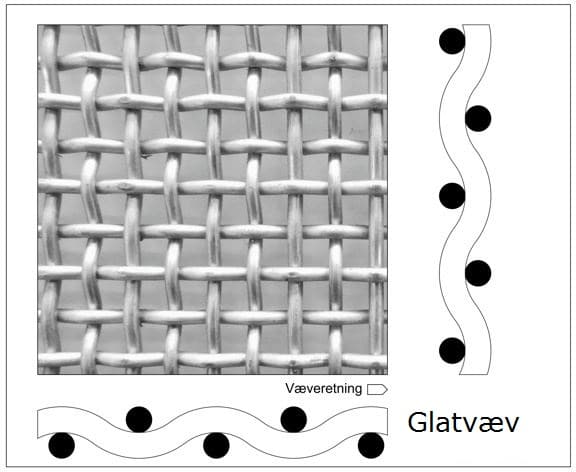

Plain Weave

Plain Weave is the most common type of woven wire mesh, and in our experience, Plain Weave is the optimal product in more than 90% of cases when we evaluate based on parameters such as:

- Function

- Quality

- Price

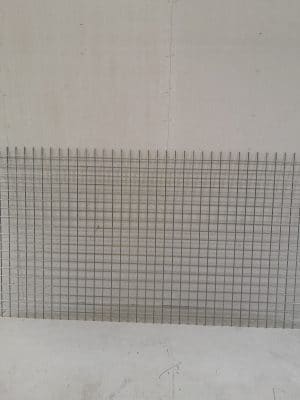

The weaving technique used to manufacture Plain Weave is the simplest where the wires cross each other alternately. Typically, leaving quadratic opening using wires with identical diameter in both directions. Minimum opening is about 0.025mm (25µ). It is relatively easy to amend the weave to the specific application, with attractive properties for welding, punching, and cutting.

Plain Weave is a simple and precise product. Strength and flow capacity can to some extent be optimized in the selection of wire diameter in combination with openings. The wire can usually not be thicker than the mesh opening.

WestCoast can supply Plain Weave from stock and/or with a short delivery time on standard weaves. We can supply custom made weave when special requirements and circumstances demands it.

Plain Weave is also known as "common weave".

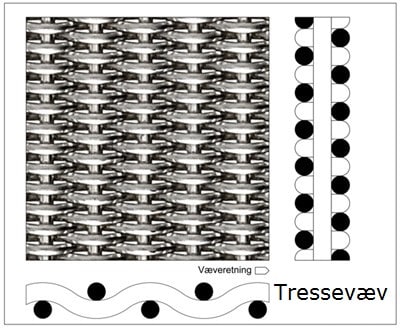

Dutch Weave

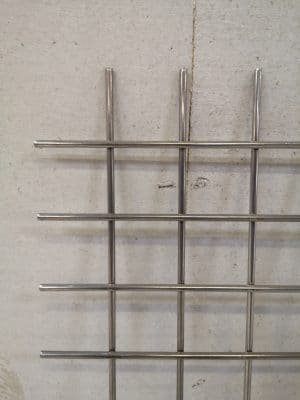

Dutch Weave has greater mechanical strength than Plain Weave. The strength comes from the wires in one direction being thicker than those in the other direction. By using different wire thicknesses, the strength of the mesh can be significantly increased while maintaining good filtration capabilities. The smallest mesh size is approximately 0.040 mm (40µ).

Examples of Dutch Weave application:

- Filtration of solid fractions / particles in a liquid

- Wire cloth for vacuum drums

- Element in a drum filter

- Insert in Nutsche filters

- Safety filter

- Element in vertical filter plates

The cleaning process of Dutch Weave is more complicated than Plain Weave.

WestCoast can supply Dutch Weave from stock and/or with a short delivery time on standard weaves. We can supply custom made weave when special requirements and circumstances demands it.

Dutch Weave is also refereed to as Hollander Weave.

Twilled Weave

The twilled weave type allows for the finest filtration compared to Plain Weave and Dutch Weave. Twilled weave can be made with small apertures by using a more complex weaving method, using thin wires, and packing the wires very closely together. Thie woven wire mesh provides high mechanical strength and is ideal for heavy-duty filtration tasks. The smallest aperture is 0.001-0.002 mm (1-2µ).

- Filtration of solid fractions / particles in a liquid

- Insert in Nutsche filters

- Element in filter cartridge

- Wire cloth for vacuum drums

As the Twilled Weave is highly compressed the open area becomes low. Consequently, the flow through the weave becomes low when the aperture is small and small particles cannot pass which can cause a buildup of impurities. In some cases it can be necessary to clean the weave with backflush, if the buildup clogs the mesh.

WestCoast can supply twilled weave from stock and/or with short delivery times for standard mesh. We can also supply custom mesh where specific requirements and conditions necessitate something different.

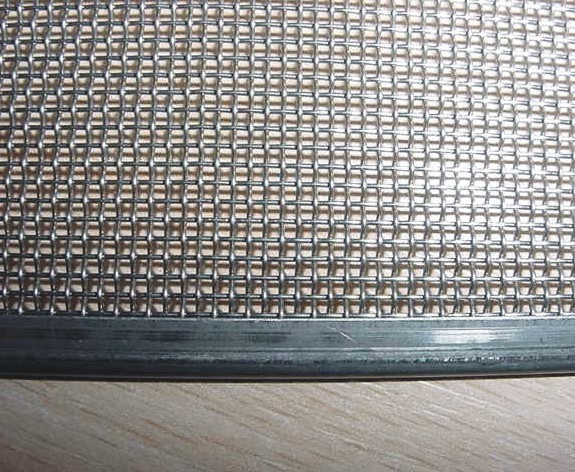

Woven wire mesh is used in a multitude of applications and is present in virtually all production processes in some form. Below is a small selection of applications where woven wire mesh is used:

- Filtration of liquids, process water, wastewater

- Cleaning of liquid products

- Processing of raw materials

- EMI/RFI shielding

- Burners (gas and boilers)

- Hydraulic systems

- Lubrication

- Drains (filter and safety)

- Insect mesh

Woven wire mesh is widely used in various industries, including:

- Food production

- Pharmaceutical industry

- Medicinal industry

- Powerplants, heat production, bioenergy

- Oil and gas

- Manufacturing of machinery and equipment

- Valves and pumps

- Gravel, stone and building materials

- Paper and cardboard

- Cocoa and coffee production

Our selection of woven wire mesh materials is the most comprehensive in Denmark. This is because we understand that choosing the right material is crucial to ensuring the optimal performance of your wire mesh. The material plays a significant role in the price, strength, heat tolerance, electrical conductivity, and corrosion resistance of your wire mesh. With our wide range of options, we believe we always have an alternative that suits your needs.

Below is a small selection of available materials:

Stainless steel: AISI 304, 316, 316L, 316Ti. Stainless steel can also be supplied within the European material tolerances, such as EN 1.4301, 1.4401, 1.4404 and 1.4571

Featured metals: Copper, brass, nickel, Monel, aluminum, duplex, Inconel, Incoloy, Hastelloy and titanium

Precious metals: Gold, silver and platinum

Other materials: Coated steel, synthetic materials such as nylon (PA), polyester (PES), or polypropylene (PP)

We have created a guide where you can find deeper insights into the different metal choices and their properties, so you can select the right metal for your needs. (please note it's in Danish only).

We understand that choosing the right material can be critical to the success of your project. Therefore, we offer a personal and non-binding assessment of your needs and options within our various material choices. Contact us at wct@wct.dk or call us at 76 12 33 66, so we can go over the options which best fit you, together

See our many stocked variants below. Use the menu on the left to find the right alternative.

At the end of the product name, “B” denotes the roll’s width in millimeters. All rolls have varying lengths but can be cut to the desired running meter, but minimum 1 meter.