In the fight against plastic in the world's oceans, WestCoast Technique has to a greater extent assisted plastic manufacturers with cleaning their process water.

As a strengthening effort, a large number of companies have joined "Operation Clean Sweep", which specifically aims to combat the amount of plastic that end up in nature and the sea.

With filters adapted to the production drains, excess plastic elements can be collected and recycled or disposed of correctly.

Vi har optimeret vores produktionsproces for at levere skræddersyede og økonomiske afløbsfiltre, der kan opsamle alle typer af faste fraktioner. Vores produktionssetup sikrer høj kvalitet og hurtig leveringstid. Vi har hjulpet en række kunder med forskellige udfordringer, herunder rensning af plastproduktionsspildevand og genanvendelse af overskydende materiale.

The drain filters were developed as a collaboration between WestCoast and a major Danish plastic supplier. The purpose was to clean a significant amount of liquid for solid fractions, without deforming or clogging the filter.

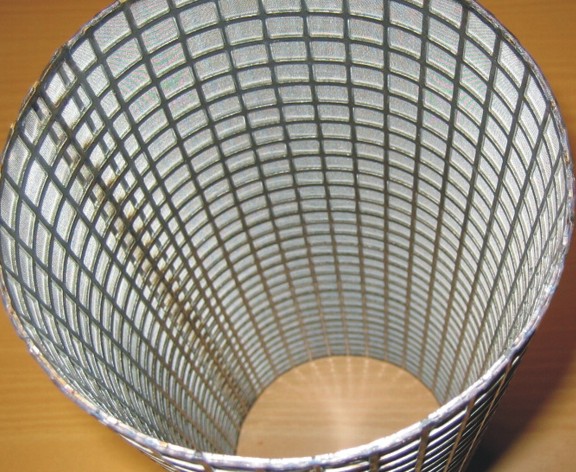

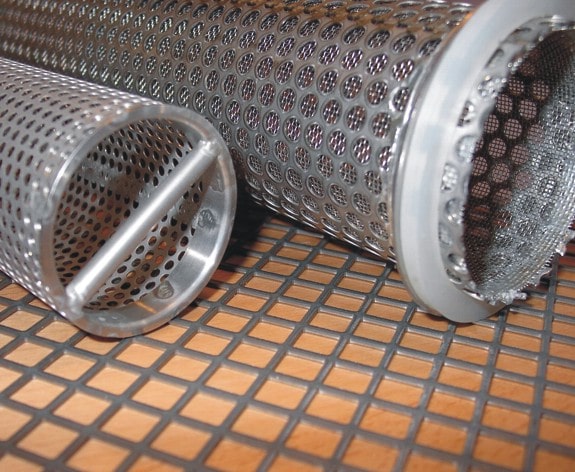

The development work resulted in a filter consisting of an inner wire mesh with small openings adapted to the solid fractions surrounded by a support plate with larger holes that ensured the necessary flow. With a focus on the strength of the filter, it was also reinforced with clamps at the bottom and a support ring at the top. Finally, different filters were designed depending on the type of drain, which could either be mounted with a classic square / round top piece / flange or silicone edge for direct mounting in drains. Since then, various mounting methods have been developed to match all known drains.

To maintain the convenience and economy of this type of filter, they are fitted with handles for quick emptying or replacement.

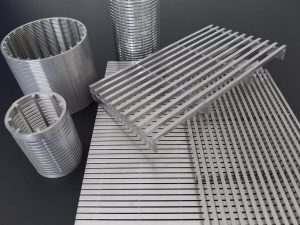

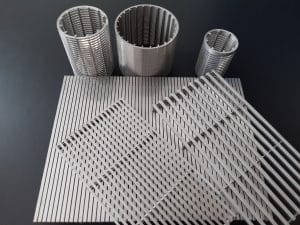

A typical alternative to drain filters are filter grates, also called wedge wire filters, which provide effective filtration as a plate.

Contact us for a chat about your filtration needs at smm@wct.dk or 76 12 33 67.

The filters can usually be produced in almost any metal or synthetic mesh types, but for the most economical solution we recommend:

- Stainless steel AISI 304 / 1.4301

- Corrosion resistant steel AISI 316 / 1.4401

- Plain steel

For increased resistance to corrosion, we recommend pickling or electro-polishing products in stainless steel, but unless otherwise stated, the products are produced without any post processing.

Drain filters are produced with a mesh opening of 0.008 mm (8 my) up to 4.10 mm. The need for mesh opening depends on the size of the solid fractions from the production.

The inner mesh is protected by an outer plate. It ensures a relatively large flow with maximum strength in relation to the mesh size. So only materials of the desired size are allowed to flow through and without immediate clogging of the filter.